Home » Carve » Tools » Power Carving Tools » Sanding Mandrels – Roll Your Own

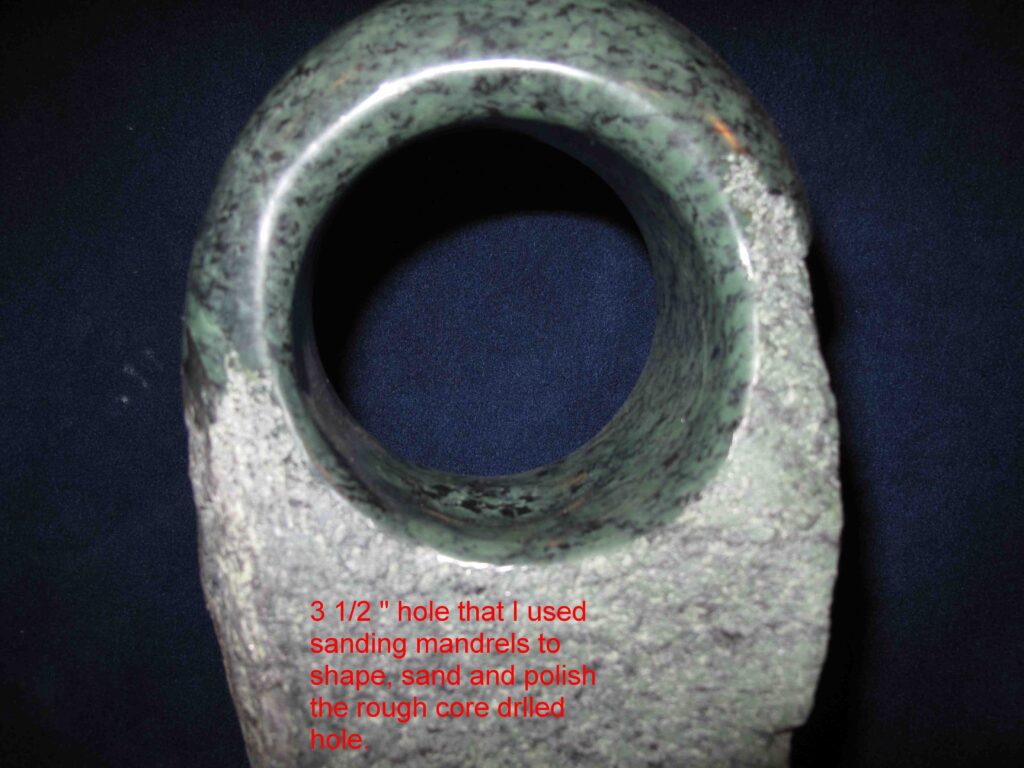

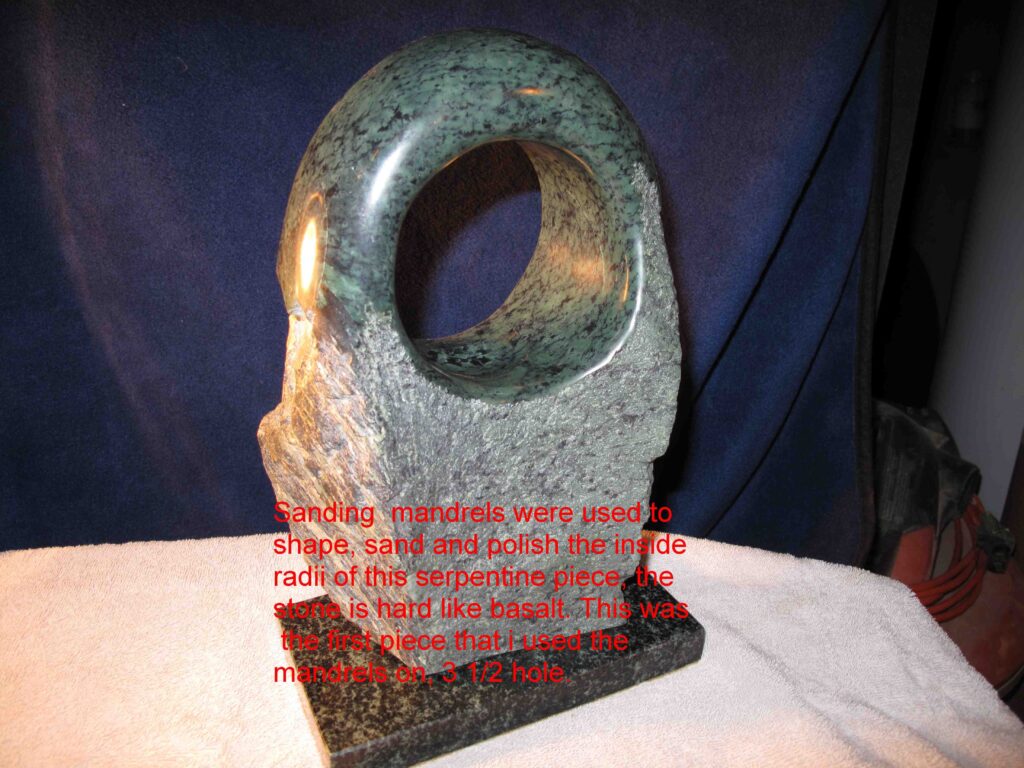

Sanding mandrels are very useful in grinding, rounding, and sanding the upper inside lips of stone vases. The transition between a flat surface and a core-drilled hole is usually sharp, rough, or even damaged. The mandrel on a die grinder allows you to shape, sand and polish this area. Presented below is how to make and use your own sanding mandrels.

I’ve broken the article into five parts: The Mandel, Sanding Material, the Crimpers, Construction, and Usage

This is the way that I make ¼ inch sanding mandrels for die grinders: I start off with ¼ ” round stock and cut a slot down the center to hold the sanding belt in place. Then I insert the belt end and tightly roll the belt on to the mandrel, stopping when the diameter is the same as that of the crimping ring. I then crimp the ring onto the sanding belt material.

I use the sanding mandrels to grind, round, and sand the upper inside lips of stone vases. The transition between the flat top and the core-drilled hole is usually sharp and rough or even damaged. The mandrel on a die grinder allows me to shape, sand and polish this area.

We need some kind of descriptive text here.