Home » Carve » Tools » Power Carving Tools » Broken Carbide Tools (chisels)

There are few sculptors who have not had the unhappy experience of breaking a carbide chisel. One’s immediate thought is to go wailing back to the dealer:

“It broke! There’s a flaw in it! Send it back to the factory and give me a new one!”

Good luck. Purveyors of carbide tooling simply do not issue guarantees. For no matter how carefully carbide sculptors’ chisels may be made or the excellence of the quality of carbide, the use to which we put them almost guarantees some breakage.

The blades and teeth of sculptors’ chisels are made of tungsten carbide. It is one of the hardest substances known, which makes it capable of holding a sharp edge far beyond the point where ordinary steel tools would become blunt. But whereas tool steel has some tensile strength, allowing it to bend, compress and stretch without coming asunder, tungsten carbide is an entirely brittle substance. When shocked beyond its limits, it fractures. But sculptors can still use their carbide chisels with great effect if they work around this limitation.

It is certain that no matter the care taken, one will experience occasional breakage; but it is almost never the fault of the manufacturer. One just has to accept the problem, buy another tool, and resolve to use more care in the future.

There are three main causes for breakage:

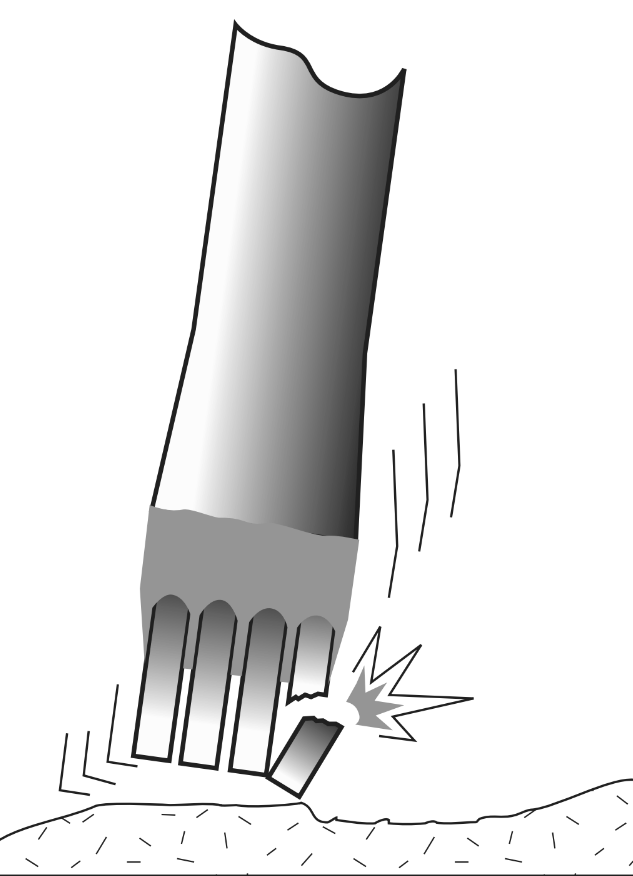

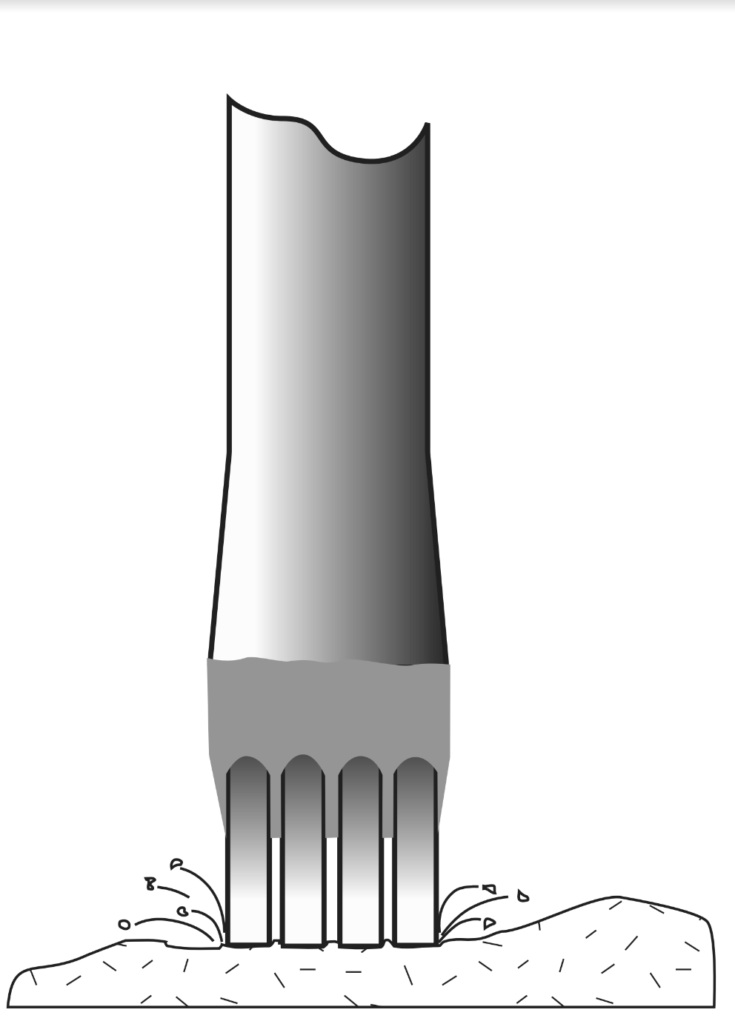

(i) Failure to apply the blade of the tool evenly to the stone. Before the hammering begins: If it is a blade chisel, the entire face of the blade should be touching the stone; if it is a tooth chisel, all the teeth should be touching the stone. Deviation from this practice will guarantee breakage.

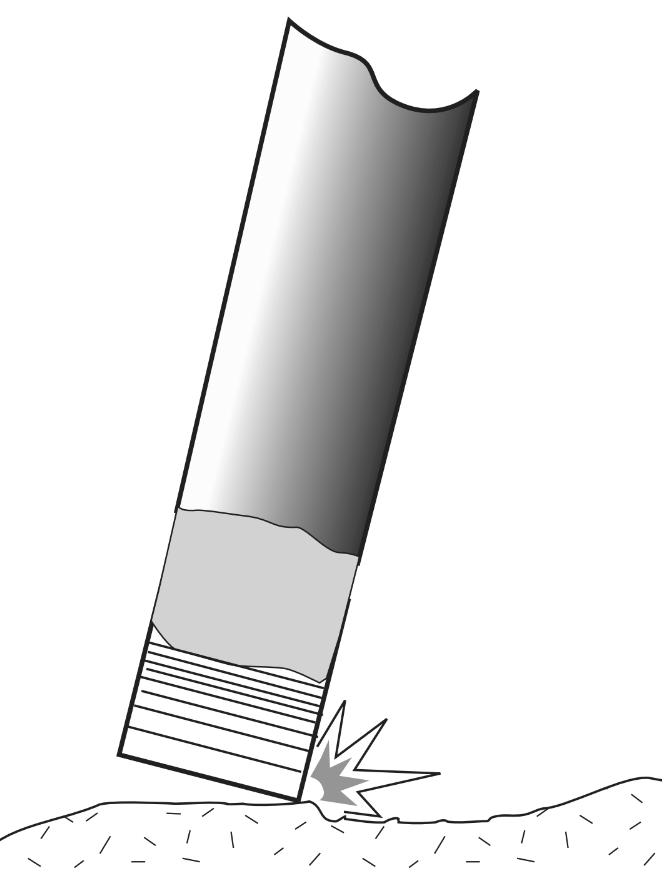

(ii) Overpowering the air hammer.

Carbide chisels work best about 85 psi and at the rated volume for the air-hammer. Excess pressure or volume will result in hitting that chisel with the same kind of force as a hand-hammer. More guaranteed breakage.

(iii) Using delicate tooth chisels on stones harder than marble. The softness of most marbles is such that slight, uncontrolled variations in the flatness of the blade-face against the work will be forgiven. It is safe to say that tooth-chisels should not at all be used on granite. Bladed chisels are usable but with the caveats of (i) and (ii). Stock removal on granite should be done with a foursquare-point chisel.

Sidebar

Carbide chisels will take endless thousands of little hits when held correctly-but they won’t take even one BIG hit, held correctly or not. That is why carbide chisels are primarily for use with air-hammers which deliver thousands of small hits as opposed to hand-hammers which deliver a few big hits.

Nor should the chisels sold for use with air hammers be used in any other way. They will not accept the shock of a hand-hammer. The striking cap that is sold for adapting to a chisel intended for air-hammers should be outlawed. It invites disaster.

There is a line of carbide chisels especially designed for hand use. They have specially beefed-up shanks and settings for the carbide blades.

See the Trow & Holden catalogue.

And on all stones, no matter their purported softness (or hardness) if it seems to you that the chisel is hitting too hard, cut back the air volume.

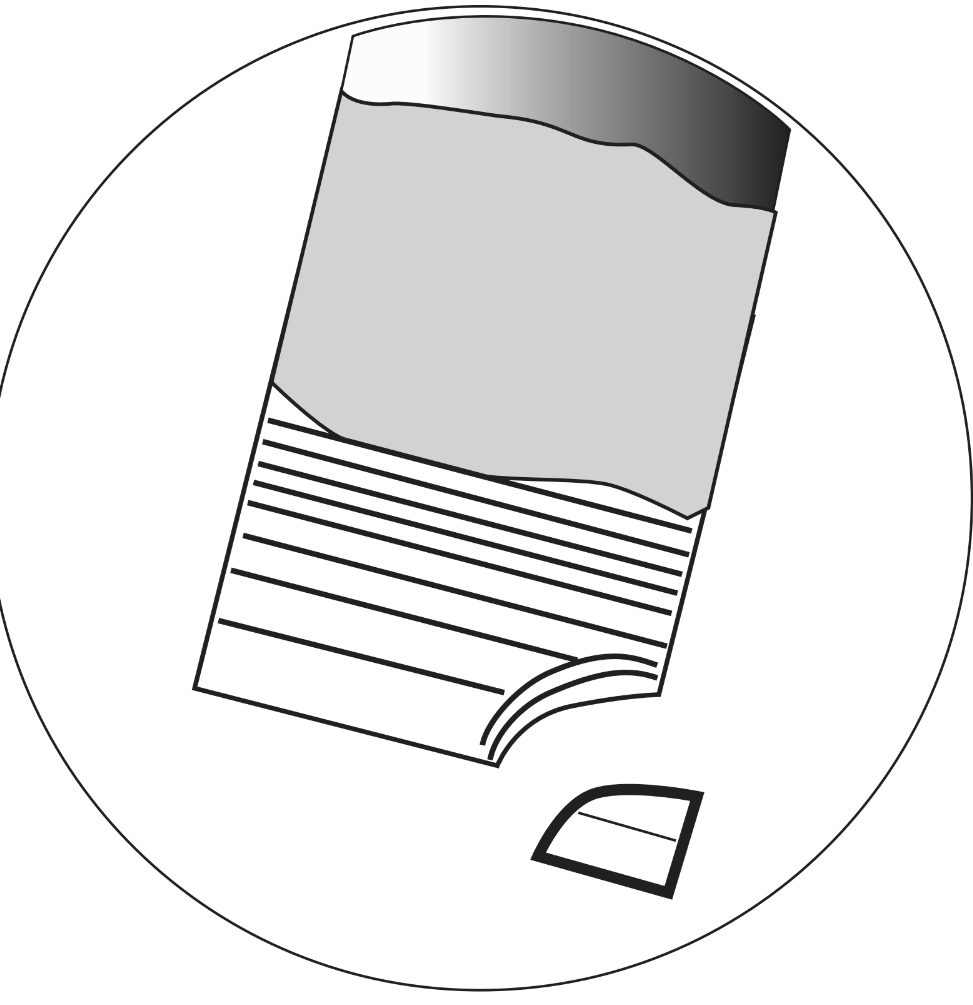

We need some kind of descriptive text here.