Home » Carve » Tools » Power Carving Tools » Air Hammers

Part of this material I used in the 20 hour granite course I taught at Pratt. Most of the info is from Tom Urban’s workshop at Camp Brotherhod, some from a workshop by Don Ramey that Hank Nelson organized at my place years ago. If you find anything useful, please add it to the article – Kirk

Pneumatic hammers

Sources:

Types:

Air consumption:

Chisel diameter:

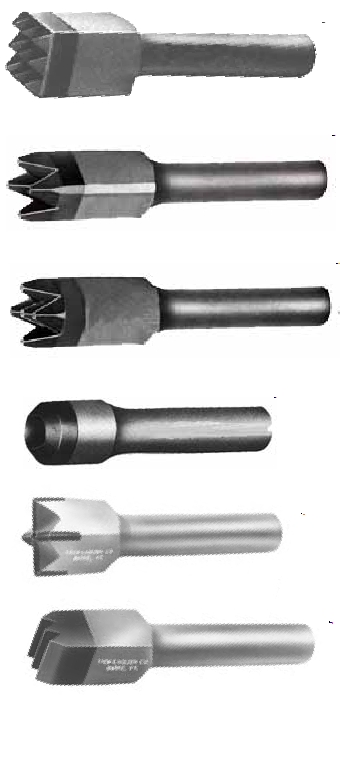

Bushing chisels:

Carving chisels:

Safety: Vibration, noise, dust & chips.

Air hammer care:

ed Note: Videos at Trow&Holden provide Pneumatic Tool Basics and Getting Started.

We need some kind of descriptive text here.